مایع متراکم کننده بتن پایه لیتیومی

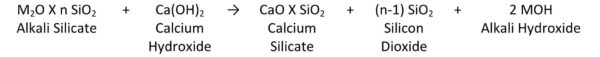

As you know, lithium silicate based hardeners have high penetration power and after the penetration of lithium silicate into the concrete texture, it begins to react with calcium hydroxide in concrete, resulting in the production of calcium silicate and lithium hydroxide. The reaction mechanism is described below.

Then lithium hydroxide is converted to lithium carbonate by absorbing atmospheric carbon dioxide, which is also insoluble in water. Which follows the reaction.

Lithium silicate based concrete hardeners have unique properties compared to other alkaline silicates due to the following properties.

Less alkaline pH of lithium silicate concrete hardeners

Very low solubility of lithium carbonate compared to sodium carbonate and potassium carbonate

Small size of lithium ion

Insolubility of lithium silicate in water after drying

Maximum ratio of SiO2 to alkali in lithium silicate compared to other alkaline silicates

Higher melting point of lithium silicate than sodium and potassium silicates

Non-participation of lithium silicate in the harmful reaction of alkali – silica (concrete cancer) due to insolubility of lithium carbonate in water due to the high solubility of sodium carbonate and potassium carbonate in water

Lack of surface moisture absorption due to insolubility of lithium carbonate in water and insolubility of lithium silicate salts after drying

Creating an environment with less alkalinity than sodium and potassium silicates (one of the disadvantages of high pH concrete environment is intensifying the reaction of alkaline silica)

Possibility of much greater penetration in concrete than sodium and potassium silicates due to the small size of lithium ions

Non-flowering due to insolubility of lithium carbonate in water

Multilingual WordPress with WPML